Introduction

If you’re familiar with forklifts and interested in learning about clamp trucks and their capabilities, you’re in the right place. Clamp trucks are essential for transporting materials such as hay, paper rolls, and other irregularly shaped items. In this guide, we will explore everything you need to know about clamp trucks, including their types, uses, and benefits.

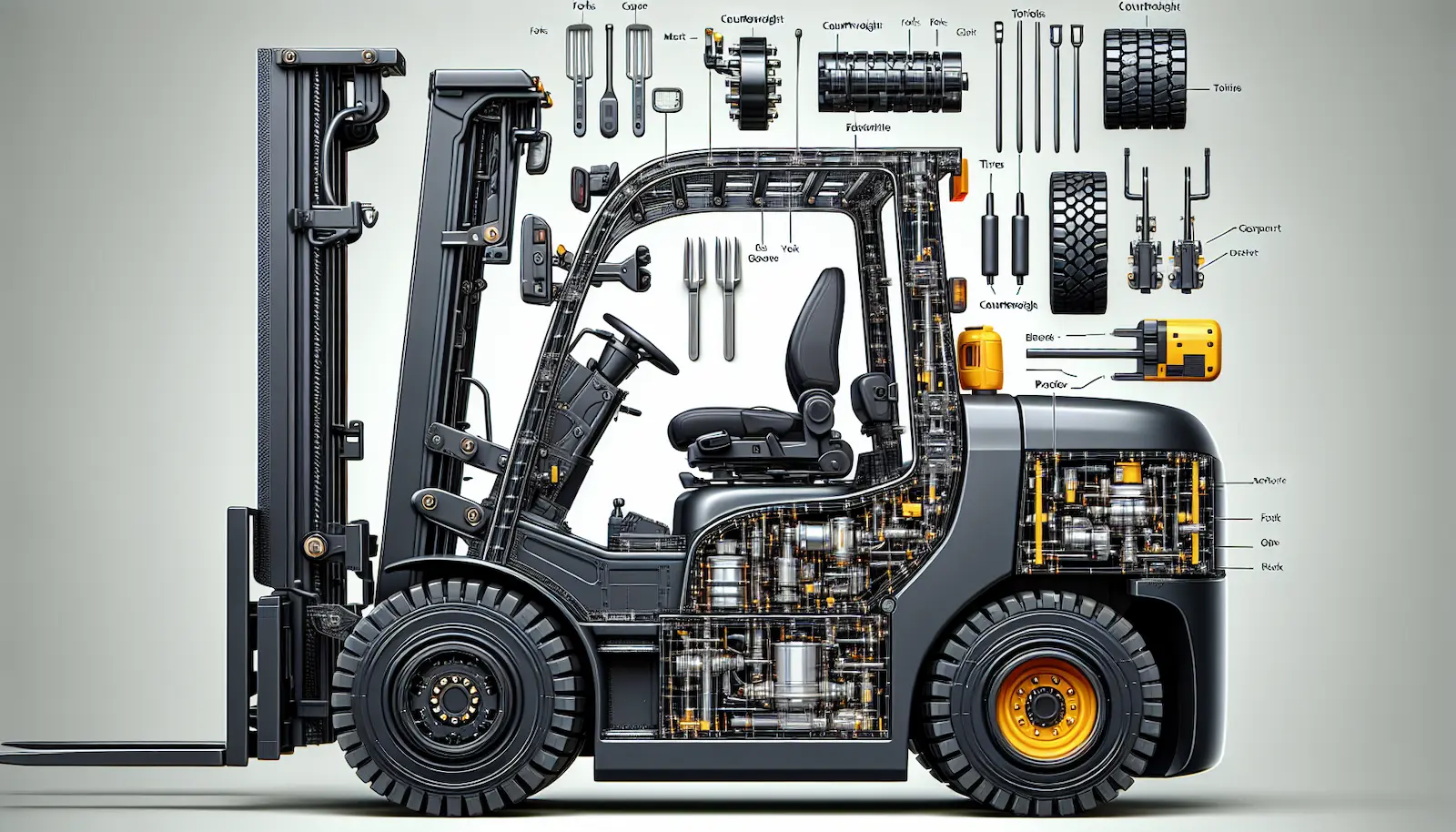

What is a Clamp Truck?

A clamp truck is a specialized forklift equipped with hydraulic-powered clamp arms designed to grasp and transport items that traditional forks cannot handle effectively. These trucks are ideal for moving bulky, irregularly shaped, or unconventional items securely.

Clamp Truck

Types of Clamp Attachments

Clamp trucks can be fitted with various types of attachments, each tailored to specific materials and handling needs:

- Carton Clamp: Perfect for handling boxes and cartons without pallets. Ideal for the food and beverage industry.

- Paper Roll Clamp: Designed to move large rolls of paper, minimizing the risk of damage.

- Appliance Clamp: Used for transporting household appliances such as refrigerators and washing machines.

- Bale Clamp: Handles materials like hay, cotton, and wool without the need for pallets.

- Concrete Block Clamp: Safely moves concrete blocks or bricks with added software components for extra security.

Applications of C

lamp Trucks

Clamp trucks are versatile tools used across various industries:

- Warehousing and Logistics: Efficiently handle and transport bulky and heavy loads.

- Manufacturing: Move materials and products through different production stages.

- Paper Industry: Safely transport large rolls of paper, preventing product damage and operator injury.

- Food and Beverage: Securely move packaged goods, ensuring stability during transport.

- Recycling: Handle bales of recyclable materials effectively.

The Power of Hydraulic Force Control (HFC)

One of the key features of clamp trucks is their hydraulic force control system. HFC automatically adjusts the clamping force based on the weight of the load, ensuring a secure grip and preventing damage. This system operates independently, eliminating the need for manual adjustments and reducing the risk of human error.

Safety Considerations

Operating a clamp truck requires attention to safety to prevent accidents and damage:

- Proper Training: Operators must receive training on equipment controls, load capacities, and safe handling practices.

- Equipment Inspection: Regularly inspect the truck and attachments for any defects or damage.

- Load Capacity: Adhere to load capacity limits to avoid instability and tip-overs.

- Proper Load Handling: Secure and balance loads correctly to maintain stability.

- Stability Awareness: Understand the principles of stability and center of gravity to prevent accidents.

Features of Clamp Trucks

Clamp trucks offer several advantages that enhance their functionality and efficiency:

- High Efficiency: Automated controls increase productivity and reduce manual labor.

- Precision Handling: Advanced control systems allow for accurate and efficient movements.

- Versatility: Adjustable clamp arms can handle a wide range of items.

- Safety and Reliability: Built to meet strict safety standards, ensuring reliable performance.

Training and Certification

Becoming a certified clamp truck operator involves specialized training from accredited providers. Training covers equipment operation, safety procedures, load handling, and maneuvering techniques. Operators must pass both written and practical exams to obtain certification, ensuring they are equipped with the necessary skills to operate safely and efficiently.

Conclusion

Clamp trucks are indispensable in industries that require handling non-palletized goods. Their ability to securely grasp and transport various items makes them a valuable asset in logistics, manufacturing, and more. Proper usage, regular maintenance, and adherence to safety protocols ensure the effective and safe operation of clamp trucks, enhancing overall productivity and reducing risks.